The Role of CAD in Streamlining Laser Cutting Processes

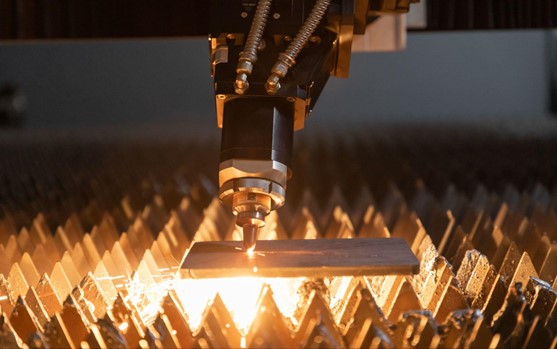

In today’s advanced manufacturing landscape, Computer-Aided Design (CAD) has become indispensable in enhancing precision and efficiency across various processes, notably in laser cutting. CAD technologies enable the seamless transformation of digital designs into real-world objects, providing unprecedented accuracy and control. This integration of CAD in laser cutting not only streamlines operations but also pushes the boundaries of what can be achieved, making complex cuts that were once deemed impractical or too costly, not only possible but routine. Through this guide, ACCURL, a high-end manufacturer of sheet metal working machinery, will equip you with a fundamental understanding of CAD technologies in laser cutting processes and their crucial role in modern manufacturing.

In today’s advanced manufacturing landscape, Computer-Aided Design (CAD) has become indispensable in enhancing precision and efficiency across various processes, notably in laser cutting. CAD technologies enable the seamless transformation of digital designs into real-world objects, providing unprecedented accuracy and control. This integration of CAD in laser cutting not only streamlines operations but also pushes the boundaries of what can be achieved, making complex cuts that were once deemed impractical or too costly, not only possible but routine. Through this guide, ACCURL, a high-end manufacturer of sheet metal working machinery, will equip you with a fundamental understanding of CAD technologies in laser cutting processes and their crucial role in modern manufacturing.

How Does CAD Enhance Laser Cutting Efficiency?

CAD software plays a pivotal role in optimizing laser cutting, offering a myriad of benefits that elevate both the performance and output quality.

Speeding Up Design to Production Cycles

With CAD, the transition from conceptual design to production is dramatically accelerated. Designers and engineers can quickly make adjustments to designs in a digital environment, reducing the time traditionally required for manual modifications and prototypes.

Reducing Errors in Cutting Specifications

CAD systems minimize the risk of human error by providing precise control over cutting specifications. This digital precision ensures that each cut is made exactly to specification, reducing waste and the need for rework.

Facilitating Complex Cuts and Designs

The versatility of CAD software allows for the execution of intricate and detailed designs that would be challenging to replicate manually. This capability is crucial in industries where complexity and precision are mandatory, such as aerospace and automotive manufacturing.

What are the Key Features of CAD Software That Benefit Laser Cutting?

CAD software is equipped with various features that specifically benefit laser cutting processes:

- Auto-nesting: Optimizes the layout of patterns to minimize material waste.

- Simulation tools: Enable virtual testing of cuts before actual production, saving resources and time.

- Standardized libraries: Offer ready-to-use templates that simplify design processes.

Integration with Laser Cutting Machinery

Modern CAD systems are designed to integrate seamlessly with laser cutting machines, allowing for direct control and adjustments during the cutting process.

Support for Multiple File Formats

Flexibility in file format compatibility ensures that CAD software can work with data from various sources, simplifying workflow integration.

Real-Time Adjustment Capabilities

CAD systems can adjust cutting paths in real-time, adapting to material inconsistencies or measurement adjustments on the fly.

Step-by-Step Guide: From CAD Design to Laser Cutting

The journey from a CAD design to the final laser-cut product involves several crucial steps:

- Preparing the CAD Design

- Consider material properties and design complexity, ensuring the design is optimized for cutting.

- Setting Up the Laser Cutter

- Configure machine settings like power, speed, and alignment based on material and design specifics.

- Executing the Cut

- Monitor the cutting process, making real-time adjustments to ensure precision and quality.

Best Practices for Integrating CAD with Laser Cutting Processes

To maximize the benefits of CAD in laser cutting, adhere to the following best practices:

- Regular software updates: Keep CAD software updated to leverage the latest features and improvements.

- Using high-quality models: Ensure that the digital models are of high quality and fully detailed to avoid errors during cutting.

Common Pitfalls and How to Avoid Them

Common challenges in CAD-driven laser cutting include misalignment and data corruption. Regular calibration of machines and backing up design files can mitigate these issues.

Comparing Different CAD Software for Laser Cutting

When selecting CAD software for laser cutting, consider the following options:

- AutoCAD: Known for its robust features and extensive support community.

- SolidWorks: Offers excellent simulation capabilities and intuitive design features.

Criteria for Choosing the Right CAD Software

Key criteria include compatibility with existing hardware, software support and updates, and specific features tailored to laser cutting needs.

The Future of CAD in Laser Cutting

The future of CAD in laser cutting looks promising with advancements like AI integration and enhanced simulation technologies poised to further revolutionize this field. Experts predict smarter, more intuitive CAD systems that can predict user needs and streamline the design-to-production cycle even more efficiently.

Case Studies: Successful Implementations of CAD in Laser Cutting

Various industries have benefited from the integration of CAD in laser cutting:

- Aerospace: Precision cuts are critical in aerospace applications, and CAD has significantly improved the production of complex components.

- Automotive: Customized parts production has been streamlined, enhancing both design flexibility and turnaround times.

Conclusion

The integration of CAD technologies in laser cutting processes has not only optimized efficiency but has also expanded the creative boundaries of manufacturing. As this technology continues to evolve, its impact on the manufacturing sector promises to grow, underscoring the critical role of CAD in modern industrial operations.