A sheet metal bending fillet is the bent part around the edge of the sheet metal bending materials, which has been rounded to remove the sharp corners. By removing the sharp corners and creating a fillet, you can join the edges of the sheet metal materials with other components with ease.

A fillet will also make the sheet metal edges look more tidy, which can affect the overall aesthetics of the hardware component you are building. Creating sheet metal fillets is a common process performed in sheet metal fabrication services.

What is Dimpling in Sheet Metal?

Dimpling in sheet metal is the process of creating holes on the sheet metal materials, which resemble the shape of dimples. These uniquely-shaped holes are useful for you to use as strong panels for your sheet metal components. Dimple dies are the primary tools you need to use for the dimpling process. You can use the press brake to press the dimple dies against the sheet metal materials to create dimples.

A wide range of industries use the dimpling process to create dimples for their sheet metal components, which include consumer electronics, medical, aerospace, automotive, and other industries. Dimples are usable as strong panels, no matter if you use thinner or thicker sheet metal materials.

What is Notching in Sheet Metal?

Notching in sheet metal working refers to the activity of removing unwanted parts of the sheet metal around the edge areas, which will allow you to create a notch shape around the edges. This is an important process to do if you need to wrap the edges of the sheet metal around to the other side, such as when you are building enclosures or containers using the sheet metal materials.

There are plenty of notch types you can create with the notching process. Various sheet metal materials are suitable for notching, such as aluminum, copper, stainless steel, and more. Notching is also a common process when you create a sheet metal prototype.

The Process of Making Dimples in Sheet Metal Bending Fillets

The dimpling process in sheet metal bending fillets is quite an easy and straightforward operation. You just need to line up the fillet with the pressing machine to create accurate dimples for it.

Here’s the step-by-step process of making dimples in sheet metal bending fillets:

-

Calculate the dimple size you need to make

Measure the dimple size in proportion of the fillet size, and keep in mind that all dimples must be located well within the sheet metal fillet area. Give some padding as necessary and avoid putting the dimples with too little spacing between them.

-

Prepare the dimple dies with suitable size

After calculating the size of the dimple, it’s time for you to prepare the dimple dies that will be suitable to create the dimples you need. You will need to use the dimple dies to make the dimple using the press machine.

-

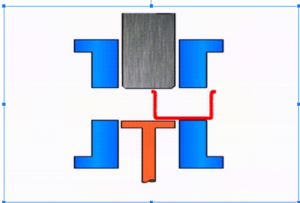

Line up the sheet metal fillet on the flat surface of the die press

Line up the sheet metal fillet with the press brake equipment. Keep the stability of the sheet metal fillet as you apply dimples with the press brake equipment.

-

Put the dimple die on the area you need to apply

Next, place the dimple die on the fillet area you need to apply. Before pressing the die, you will need to ensure that you are placing it in the exact area that requires dimpling.

-

Press the dimple die on the sheet metal fillet

After confirming the placement of the fillet, now you can press the dimple die on the sheet metal fillet. You can make as many dimples as you need.

-

Complete the dimpling process

You just need to complete the process for the remainder of the dimpling operations. You will need to switch to different dimple dies if you need to change the dimple size during this process.

The Process of Making Notches in Sheet Metal Bending Fillets

The notching process is quite different from the dimpling process in sheet metal working. There are various ways you can perform the notching process.

Here’s the step-by-step process of making notches in sheet metal bending fillets:

-

Prepare the sheet metal fillet

First, you will need to prepare the sheet metal fillets you would like to notch using the notching equipment. You can categorize the fillets based on the notch types you would like to apply.

-

Consider the notch type you would like to apply

There are various notch types you can apply, such as V-notch, square notch, straight notch, tube notch, and wire notch. Each notch type will give you a distinct shape and different benefits.

-

Consider the equipment you would like to use for notching

The notching process can be done in various ways, such as by using a corner notcher, turret punch press, and laser cutter. It’s important for you to consider the equipment you would like to use for applying notches in your sheet metal fillets.

-

Put the sheet metal fillet on the notching equipment

Now that you have decided which equipment and which type of notch you would like to make, you can put the sheet metal fillet on the notching equipment. You can configure the equipment to work on the notching process as per your design requirements.

-

Apply the notch according to your notching requirements

Next, you can apply the notch by following your design requirements using the equipment and notch type of your choice. Do this one by one until you have all your sheet metal fillets notched as needed.

Conclusion

Dimpling and notching are simple processes that involve using certain pressing equipment to create dimples and notches in your sheet metal materials. You can also apply them around the fillet areas with some adjustments.

TEAM Rapid provides various types of sheet metal working and prototyping services, which include notching and dimpling. Aside from that, we also offer other types of manufacturing services, such as injection molding, die casting, and CNC machining.