Injection Molded Parts

3D Model and Injection molding

I have designed many injection molded parts. It is important to understand the properties of injection molding, like constant wall thickness and draft angles. Below are a few recent injection molded products we have designed:

Lettuce Gizmo (lettucegizmo.com)

This product is a tool that enables someone to create their own bagged lettuce. It consists of 16 slots that you insert a knife into to cut down on the lettuce. These 16 slots are divided into 4 sections of 4 slots. Each section is formed by a separate “slide” action in the tool that needs to have the proper draft. This draft must be along the line that the slide moves. If we call the z-axis up/down, the slides would move along the +x, -x, +y and -y axis’s respectively.

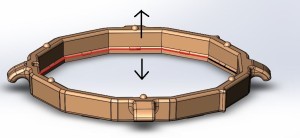

Ring for Tolicap (Tolicap.com)

The ring component is a piece of the Tolicap aerosol cap protection system. This ring is basically a “spacer” so that the Tolicap will fit different sized aerosol caps. This is a good part to explain what a parting line is.

A parting line is where the 2 halves of the mold come together. On this part, the parting line is where I drew the red line. All features above this line must be drafted upward so that the steel that forms that side of the part can be removed. The opposite is true of the bottom half.